MPO/MTP 16F&32F 400G Fiber Optic Cable

16 core MPO / MTP fiber Optic Cable is a new type of fiber assemblies to support 400G transmission, the basic MPO trunking systems are available in 8, 12 and 24-fiber variants.

- Comply Telcordia GR-326 Core, TIA 604-18 and IEC(61754-3) standards

- Highest density physical contact for multi-fiber connectors

- Support 400G transmission for Hyperscale Data Center

- Deploy directly into 16x25G active devices

- Satisfies client’s needs in different industries including singlemode(OS2) & multimode (OM1 ~ OM5) with customized length and structure

Overview

High density 16 core MPO / MTP fiber trunk cable can directly couple into 16x25G active devices, which complied by TelcordiaGR-326 Core, TIA 604-18 (FOCIS 18) and IEC(61754-7-3) standards.

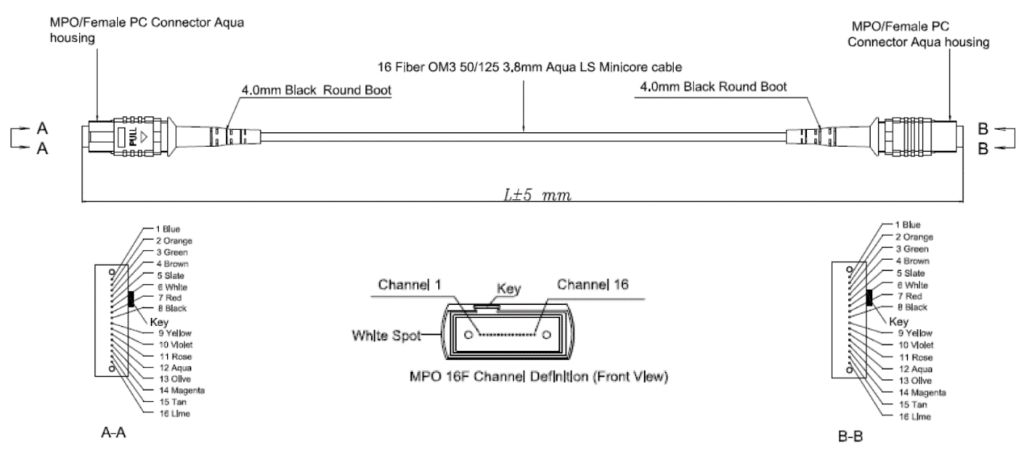

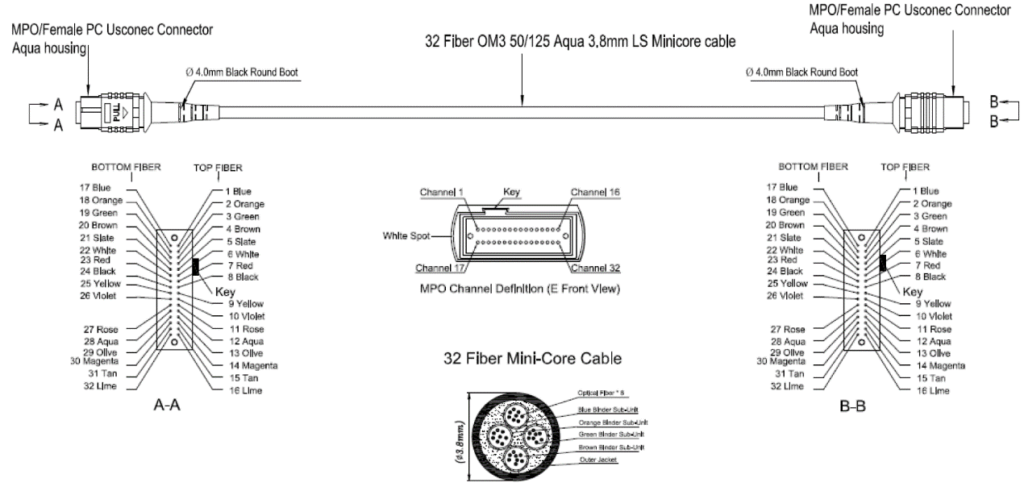

The assemblies are offered in single row 16-fiber and 32-fiber (2×16) configurations to achieve the highest density physical contact for multi-fiber connectors in the market. Karono provides the industry-leading density 16-core MTP/MPO fiber optic cable assemblies and 32-fiber (2×16) MTP/MPO fiber optic cable assemblies.

Assembly Structure Details

Typical Applications

MPO16 / MTP-16 Fiber Optic Cable FAQs

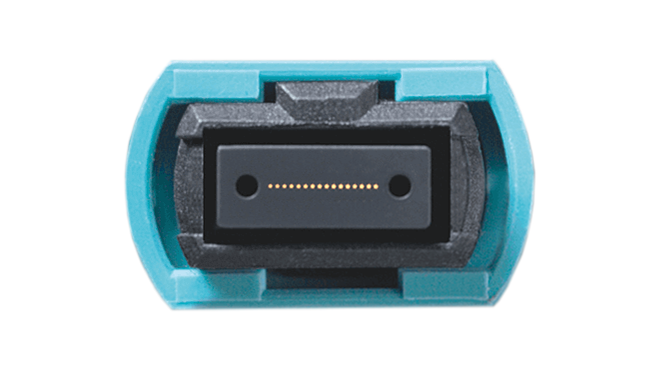

The MPO/ MTP 16 connector family encompasses the 16 fiber MT ferrule, connector hardware,and bulkhead adapters. Utilizing the same external footprint as the existing traditional 12 fiber MT ferrule, the 16 fiber MT is available in one or two rows of 16 fibers and leverages all the proven features and technology of our traditional PPS MT ferrules.

The connector hardware offers a unique keying feature as opposed to the centered keying feature on the traditional MPO hardware. This new keying design, standardized

by TIA 604-18 (FOCIS 18) and IEC (61754-7-3), ensures proper mating of the MPO-16 / MTP-16 connector without inadvertently mating the 16 fiber connector hardware with standard MPO compliant hardware. MPO/ MTP 16 adapters are available in full or reduced flange mountingand opposed or aligned key orientation

The MPO/ MTP 16 connector family encompasses the 16 fiber MT ferrule, connector hardware,and bulkhead adapters. Utilizing the same external footprint as the existing traditional 12 fiber MT ferrule, the 16 fiber MT is available in one or two rows of 16 fibers and leverages all the proven features and technology of our traditional PPS MT ferrules.

The connector hardware offers a unique keying feature as opposed to the centered keying feature on the traditional MPO hardware. This new keying design, standardized

by TIA 604-18 (FOCIS 18) and IEC (61754-7-3), ensures proper mating of the MPO-16 / MTP-16 connector without inadvertently mating the 16 fiber connector hardware with standard MPO compliant hardware. MPO/ MTP 16 adapters are available in full or reduced flange mountingand opposed or aligned key orientation- Aggregation of multiple 8 fiber parallel optic transceivers

- Direct coupling to emerging 16 fiber parallel optic links

- (8 Tx / 8 Rx, e.g. 400G QSFP-DD, OSFP)

- High density structured cabling applications

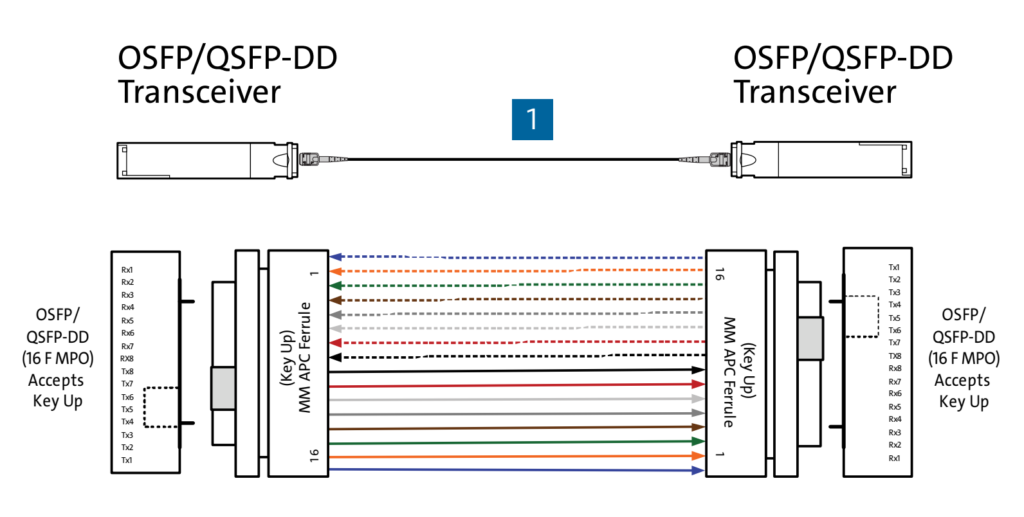

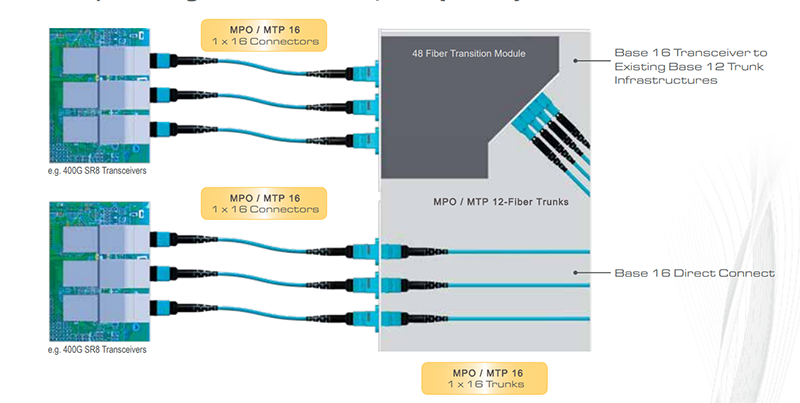

Sample Configurations for SR8, DR8 (PSM8)

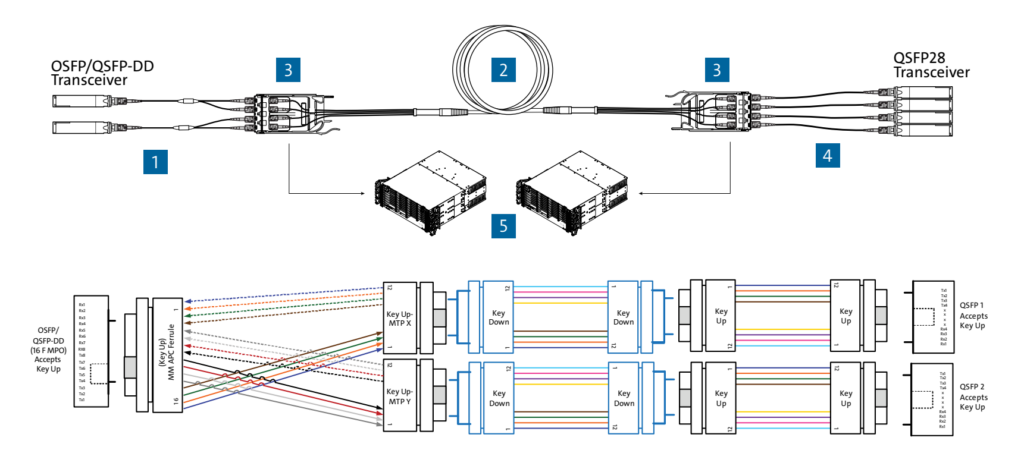

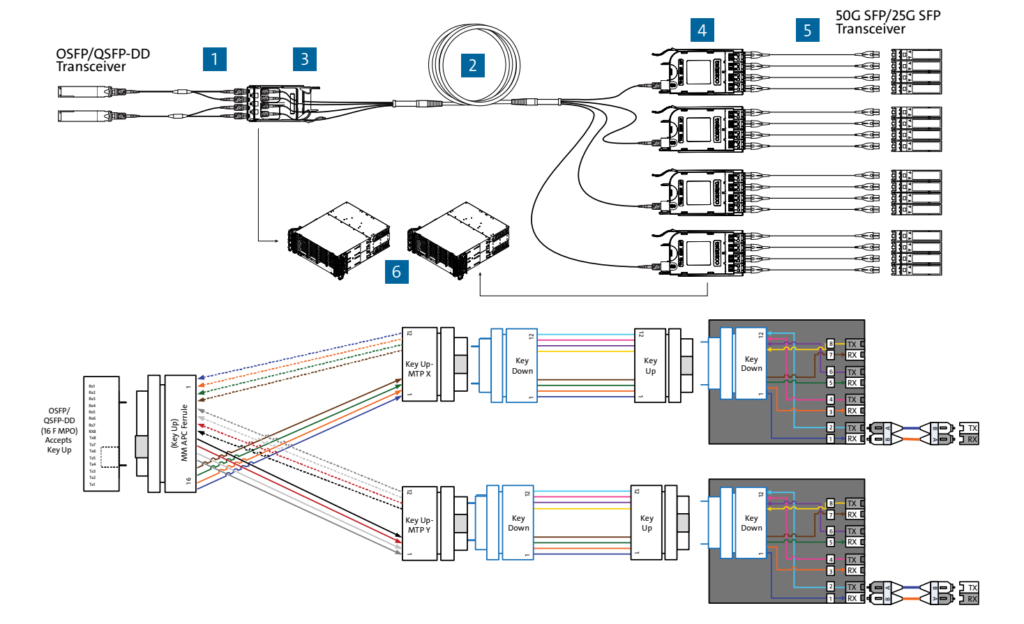

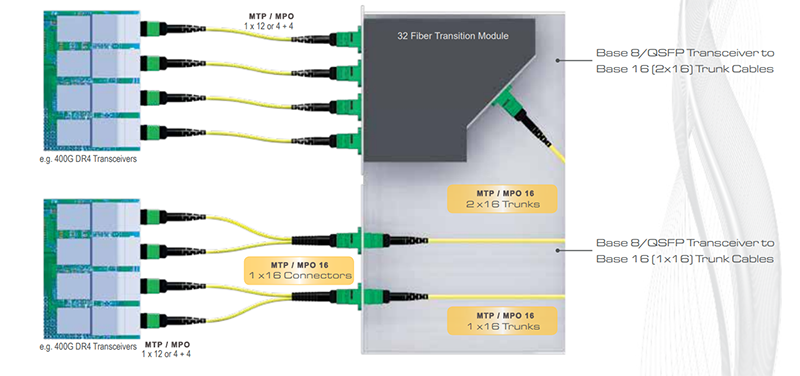

Sample Configurations for SR4, DR4 (PSM4)

• 1x16 and 2x16 fiber MT ferrules

• Highest density physical contact

• Same external footprint as traditional MT ferrules

• Fiber pitch: 0.25mm within the row; 0.50mm between rows

• Available in MM, MM APC, and SM APC

• Extremely low hygroscopic material for exceptional environmental stability

• Connector latching optimized to reduce debris generation

• US Conec patented elliptical guide pin shape

• SC footprint cutout flanged and reduced flanged adapters

EN

EN ES

ES DE

DE

3.3ft MTP/MPO 16-Fiber 400G 50/125 OM3 Multi-mode Fiber Optic Patch Cabe - Aqua, Type-B (1M)

3.3ft MTP/MPO 16-Fiber 400G 50/125 OM3 Multi-mode Fiber Optic Patch Cabe - Aqua, Type-B (1M)