MPO (Multifiber Pull Off) was the first generation of MTP designed by NTT. It is now the name of the category of multi-fiber connectors produced by several companies. MTP (Mechanical Transfer Pull Off), however, is USCONEC’s trade name for their own superior style of MPO connector.

What is an MPO connector?

MPO is the industry acronym for “multi-fiber push on.” These connectors have more than 1 fibre in a single ferrule and snap into place by a mechanical mechanism.

There are many designs of MPO on the market for the various manufacturers. As with any type of connectivity product, the performance and cost of these vary considerably and some have distinct features that enable better “overlife” performance. Some MPO connectors are inter-matable with different makes/brands, others are not. This intermateability is dependent on how close the design is to the standard.

For a complete definition of MPO connectors search out

IEC-61754-7 and EIA/TIA-604-5 (aka FOCIS 5).

MT ferrule?

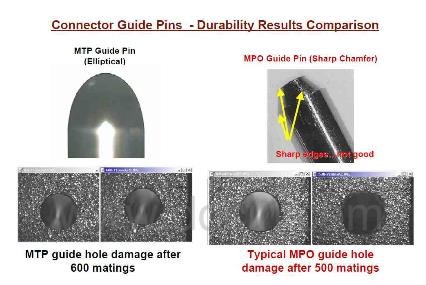

MT stands for mechanical transfer and an MT ferrule is a multi-fibre (usually 12 fibres) ferrule. The performance of the connector is determined by the fibre alignment and how this alignment is maintained after connection. Ultimately, the alignment is determined by the eccentricity and pitch of the fibre and how accurately the guide pins keep the fibres together during mating. The performance of any MPO connector can be improved if the tolerances of the pins and the moulding processes are reduced during manufacture.

The MTP® connector?

The MTP connector is a high performance MPO connector with multiple engineered product enhancements to improve optical and mechanical performance when compared to generic MPO connectors. The MTP connector is in complete compliance with all MPO connector standards including the EIA/TIA-604-5 FOCIS 5 and the IEC-61754-7.

MPO style connectors that are compliant to industry standards are inter-mateable with the MTP connector. This means that changing from 1 style connector to the MTP connector and getting higher levels of performance is possible.

Most older designed MPO connectors are limited in performance and are not able to offer the high performance levels of the MTP connector.

Why is the MTP connector described as a high performance MPO connector?

There are features on the MTP connector that have been specially designed to give improved performance and better usability over generic MPO connectors. These design features are unique to the MTP and are patent protected. The key features are described below: –

1. The MTP connector housing is removable.

· Re-work and re-polish of the MT ferrule ensures overlife performance.

· The gender can be changed after assembly or even in the field giving flexibility at point of use.

· The ferrule is scanned interferometrically after assembly

2. The MTP connector offers ferrule float to improve mechanical performance. This allows two mated ferruled to maintain physical contact while under an applied load. (US Patent 6,085,003)

3. The MTP connector uses tightly held tolerance stainless steel elliptical guide pin tips. The elliptical shaped guide pin tips improves guidance and reduces guide hole wear. (US Patent 6,886,988)

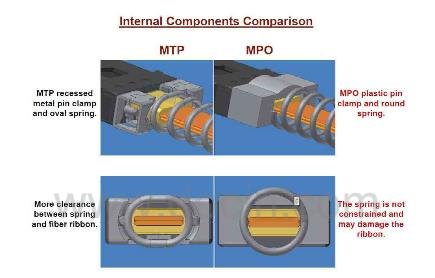

4. The MTP connector has a metal pin clamp with features for centering the push spring. This feature:

· Eliminates lost pins

· Centers the spring force

· Eliminates fibre damage from the spring mechanism

5. The MTP connector spring design maximizes ribbon clearance for twelve fibre and multifibre ribbon applications to prevent fibre damage.

6. The MTP connector is offered with four standard variations of strain relief boot giving more flexibility over the cable used

· A round loose fibre cable construction

· Oval Jacketed Cable

· Bare Ribbon Fiber

· Short boot which reduces the footprint by 45%. Ideal for use in space limited applications.

Are MT ferrules cleaned in the same way as standard connectors?

The best method available for cleaning MT ferrules to remove dust and oils which reduce optical performance is the use of an advanced dry cloth cleaning system like the NTT-AT OPTIPOP.

The cleaning method is very simple as it involves a single pass. When using the recoomended cleaning system contaminents are completely removed as opposed to using low grade cloths or swabs which just move the contaminents away from the fibres but leave them on the ferrule face.

The OPTIPOP family of cleaners are designed for use with both male and female connections and have options for single fibre ceramic ferrule connectors as well. The OPTIPOP cassette and card cleaners allow the owner to refill the cleaning clothes which can reduce cost per cleaning below traditional cleaning methods.

EN

EN ES

ES DE

DE